GC-BS1903

Size:230X158cm

Shell: 210T rip-stop polyester Water repellant

Lining: 100% cotton flannel

Filling:Hollow fiber 350g/㎡

Packing: Compress sack bag

Feature

• Lining made of 100% cotton flannel, breathable, warm and soft

• King size for 2 adult with hood.

• Could be open in two sides for each in & out.

• Fit for 4 season

• Good for car/Van/Caravan camping.

We are manufacturer and whole seller not retailer

GREEN CAMPING PORDUCTS CO.,LTD is established in 2010 in Changzhou city, Jiangsu province, China. Which is specialized in tent, sleeping bag, picnic blanket and some camping accessories. There are around 130 workers in our factory.

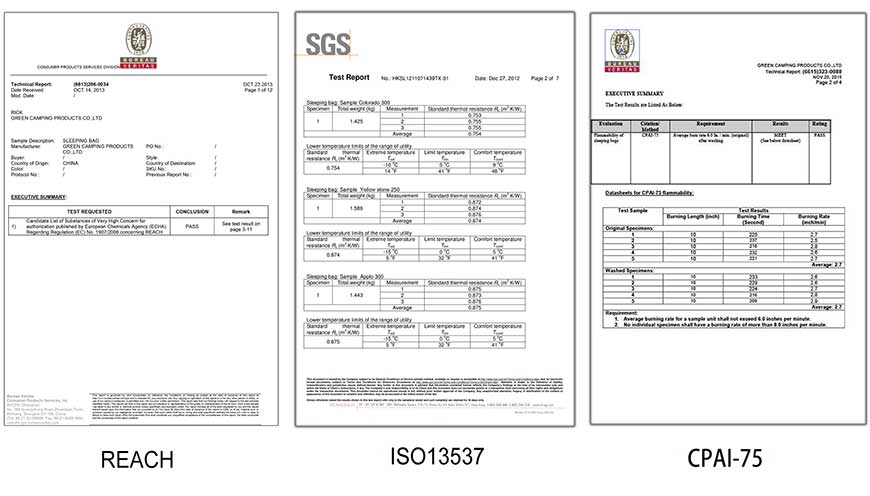

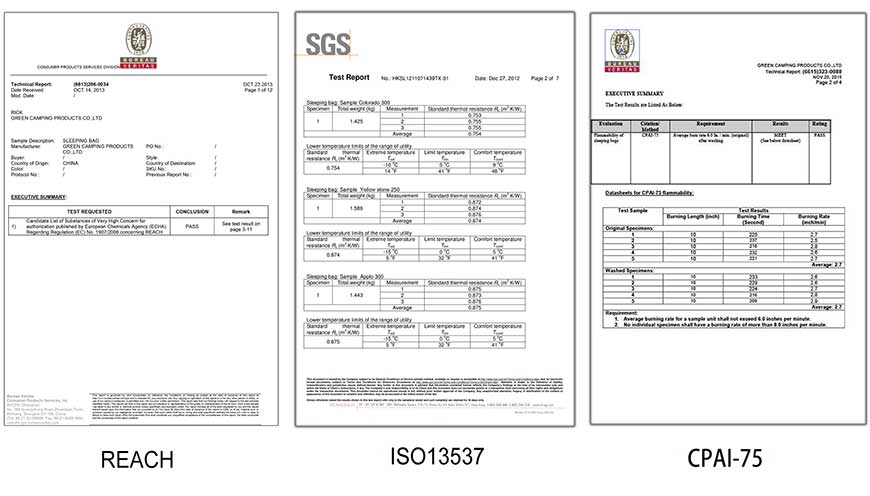

We dedicated ourselves to provide qualify & safety products. Both organization chart and workflow are powered by this goal. All the products are inspected one by one before shipment. Most of the our products have passed the relative test requested by European market and North America market, including AZO, CADMIUM, PAHs, PFAS, LEAD CONTENT, REACH, PHTHALATES, FORMALDEHYDE, EN13537, EN71, CPAI-84, CPAI-75, ISO5912.

Our good quality products and faithful business style earned us many customers, including Eureka, Nordisk, Red fox, Obelink, E. Leclerc, Rusta, UNHCR, LIONS international, Military department from different countries…, if you think it is important to you, please don’t hesitate to contact us!

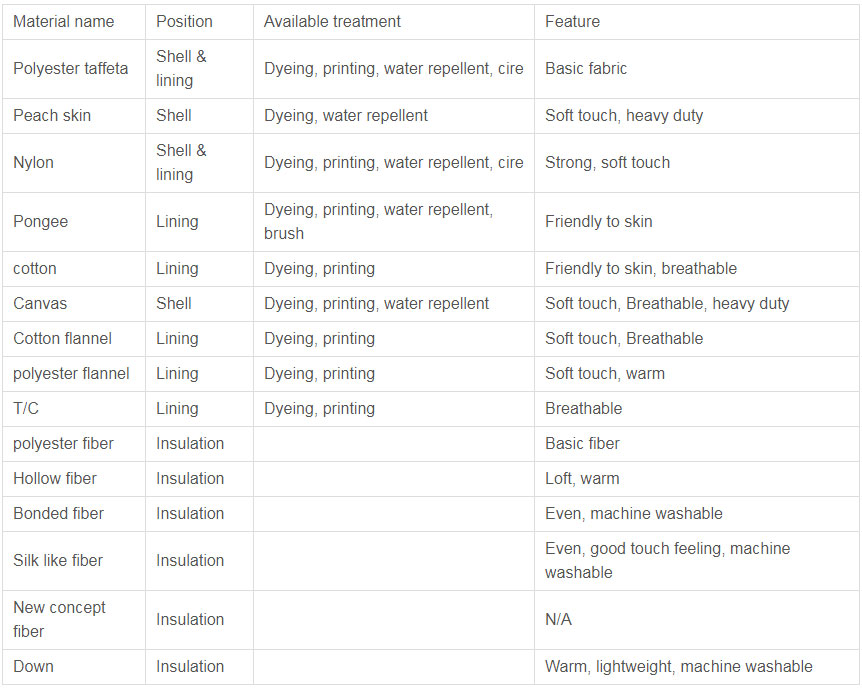

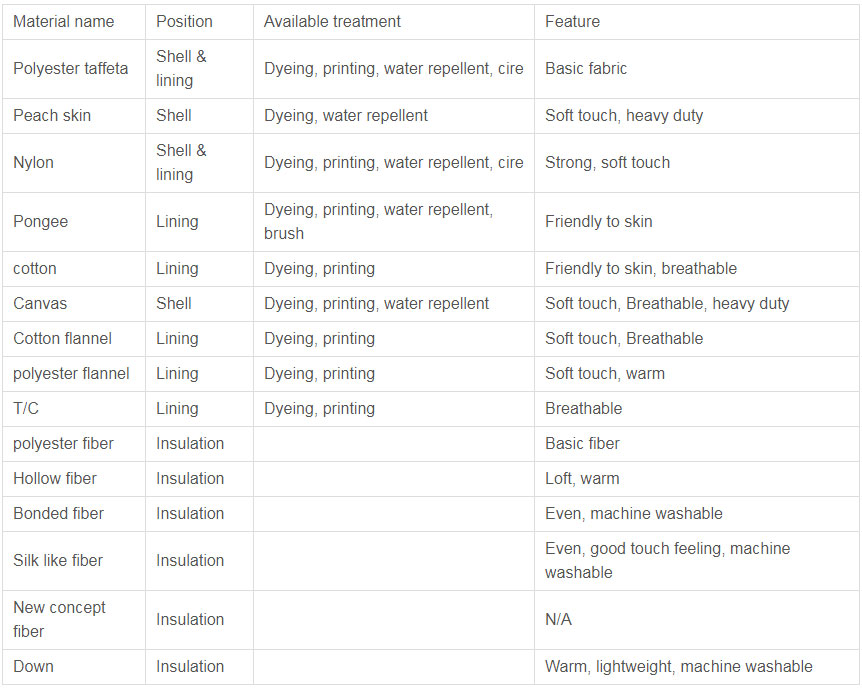

Below are most used materials for sleeping bag:

Remark:

1. Some of polyester taffeta, nylon are rip-stopped, you can see the check at this kind of fabric, because there are double or triple yarn at ridge, which make the fabric stronger and prevent for tearing.

2. Fabric normally measured by how many “T” and “D”. “T” means quantity of yarn at one square inch, big number means big density. “D” means diameter of yarn, big number means big diameter.

FAQS

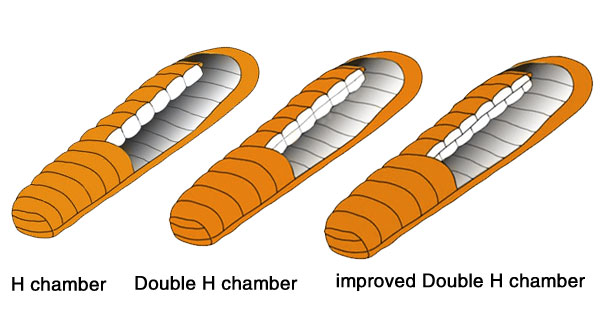

1. Do you know how many kind of sewing structures of sleeping bag? What is difference?

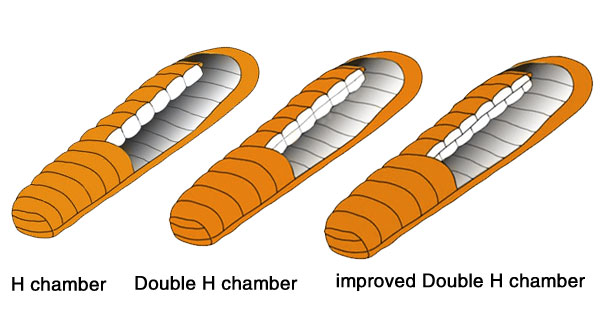

What’s the sewing structure of your sleeping bag? Is that fit well for your purpose? Does your supplier told you which structure is used for your sleeping bag and feature of each structure? Normally, there are 2 different structures on the market, the H chamber and double H chamber.

The H Chamber is simplest and most popular structure, sew the shell, insulation and lining together directly. This structure is usually used for summer-spring models

Double H chamber, which is most popular used for low temperature sleeping bag. There are 2 separate layers, the outer layer sew shell & one layer of insulation together and the inner layer sew lining and another layer of insulation together, then sew 2 layers together. This double H structure could have more insulation and better performance than H chamber to keep sleeping bag warmer. After lots of thermal insulation test with “thermal dummy”, we find there’s still “Cold Points”, so we apply an improved double H structure.

Improved double H chamber, as it’s name shows, it’s improved based on double H chamber. The sewing line on double H for both 2 layers are at same level, thermal will loss through these “cold pints”. In order to solve this problem, we designed this improved double H chamber.

2.Does your sleeping bag waterproof?

If somebody tell you that their sleeping bag is waterproof, you should consider if he/she is in this line. Sleeping bag should NOT waterproof, it need to be water repellent and breathable. If a sleeping bag is waterproof, it will not breathable exclusive some extremely high level fabric. The consumer will sweat and feel very uncomfortable.

3.Does your sleeping bag machine washable? We has some complaints even my supplier told me their sleeping bag is machine washable.

It depend on different sleeping bag structure and different material used for. Please feel free let us know if you want a machine washable sleeping bag.

4. What is your minimum order quantity?

The minimum order quantity depend on different items and product details. Normally from 1000pcs , some items more, some less. Please contact us for each different item.

5. What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 45-60 days after receiving the deposit payment. The lead time effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with our staff. In all cases we will try to accommodate your needs. In most cases we are able to do so.

You are here:

You are here:

+86-519-81580651

+86-519-81580651 No 168-3, North Qingyang road, Changzhou,

No 168-3, North Qingyang road, Changzhou, info@greencampchina.com

info@greencampchina.com +86-519-81580652

+86-519-81580652